So, armed with a Phillips screwdriver, I removed a bajillion screws to remove the back plate.

The nine short screws around the edge hold the plate down. Five sunken longer screws in the middle seem to be for holding the keys in place--it's probably possible, in retrospect, to remove the keys after taking out only these five. The other four long screws? I have no idea.

I immediately saw that what had been rattling was a small "piggyback" board.

Fortunately, the board is somewhat secured by a metal hook (lower left). Score one for Korg engineering design! Working gingerly so as not to bend any pin in its three sets of sockets, I pressed the board back into its place.

"Hm," I wondered, "'Korg 64 Voice Board' sounds awfully important, yet I've been playing without it all this time!" But now it was time to figure out how to get the keys out.

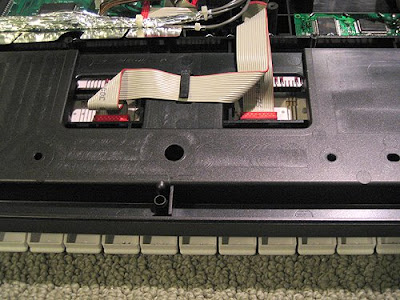

Without the five screws to the back plate, the keys remain connected only by two ribbon cables. Not having a proper ribbon cable connector tool, I carefully pulled them out with wide-opening pliers. I made sure to note that the ground (red) wire in the ribbon was oriented to the right on each.

Now the keys were free to slide down and out.

The keys are held in place simply with dart-shaped springs that are fairly easy to pluck out. The key itself then detaches up in back and then forward of its hook in front. Underneath the keys is a strip of circuit boards with a thinner strip of molded rubber on top (left in photo). I'd found the famous "pressure strip."

I removed all the keys between the two that weren't working (middle C to the offending B above it).

There are seven uniquely shaped white keys and a single unique black one. Fortunately for me, the white keys are all labeled with their note in the scale. It seemed to me that the springs for the black keys were shorter, so I kept them segregated.

The rubber pressure strip simply peels off. It seems to be cut to length as needed. To reattach, you'll need a specialized instrument called a bent paper clip. With it, I first pushed in the larger rubber plugs on the strip, then finished with the small ones.

On the under side of the rubber pressure strip are two circular electric contacts that, when the key is pressed, short corresponding pairs of contacts on the circuit boards. Looking at the pressure strip contacts under my B key, I found the problem.

A good sized chunk of crud, to be sure. I scrubbed each set of contacts with a chamois q-tip meant for cleaning the heads of tape recorders. That way I wouldn't leave any lint (protocrud) behind.

I didn't mess with contacts for the other keys. If it ain't broke, don't fix it...

Just as a matter of interest, I noticed that the rear contact is longer than the front one. The small gap of time between the two contacts hitting is how the keyboard judges the velocity of a key when it is pressed.

Enough poking around! I reversed the order of disassembly, taking special care to make sure the springs were seated properly and evenly. Power up, and everything is working better than before. I no longer have notes drop as I add to chords; no doubt due to having 64 voices now at my disposal. :P A very good result considering I really had very little idea of what I was doing when I opened up the keyboard to begin with!